BAE Systems and University Hospitals of Morecambe Bay NHS Foundation Trust (UHMBT) collaborate to develop the ‘Morecambe Bay Hood’ – a Powered Air Purifying Respirator (PAPR) for NHS staff

- UHMBT says UK-made PAPR is a “game-changer”, which boosts workers’ safety and enables more compassionate care

- Project follows BAE Systems’ development of 3D printed face shields and curtain hooks during COVID-19 pandemic.

Engineers from BAE Systems’ Submarines business, along with local company Lancastle and staff from University Hospitals of Morecambe Bay NHS Foundation Trust (UHMBT), have developed pioneering new Personal Protective Equipment (PPE) for staff on COVID-19 wards.

In just 11 months the project has gone from concept to the Morecambe Bay Hood gaining Health and Safety Executive (HSE) approval for use during the pandemic. BAE Systems and Lancastle have designed the hood free of charge, with the hoods being rolled out to hospital wards in Lancashire and South Cumbria over the next few weeks.

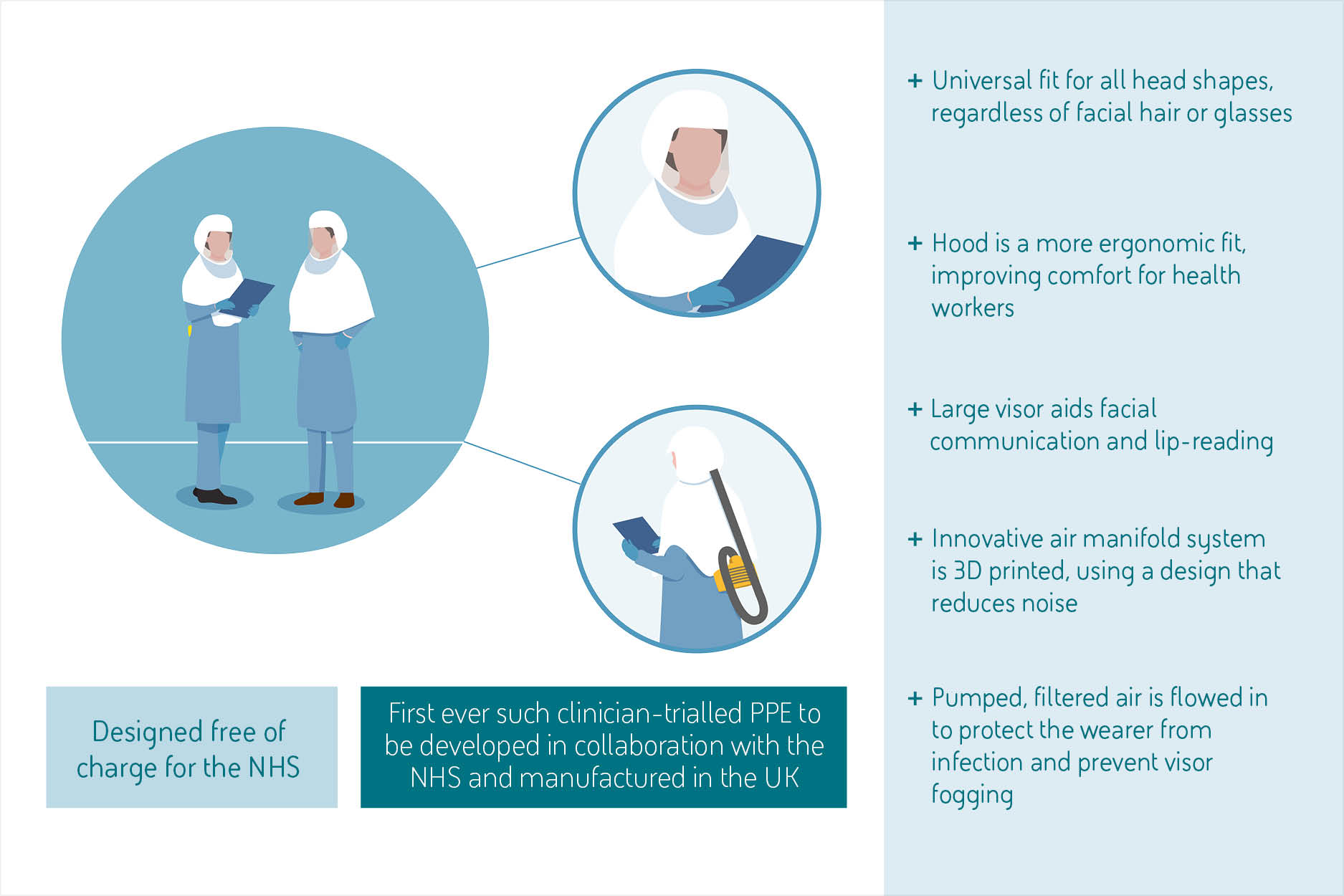

Developed to replace current PPE hoods, which were created for an industrial rather than a clinical environment, the Morecambe Bay Hood is less expensive, is fully cleanable, reusable and offers greater protection and comfort to healthcare workers as the hood is suitable for all face shapes and sizes.

The design - a full-face protective hood delivering a continuous stream of clean filtered air - significantly reduces ‘fogging’ and aids improved communication and empathy between healthcare staff and patients because facial expressions can be seen more clearly and lip-reading is easier.

Stuart Hosking-Durn, Head of Resilience and Patient Flow for UHMBT, said: “The dedication of our frontline workers has been instrumental in fighting COVID-19, but the Morecambe Bay Hood will be an absolute game-changer for us as we continue to care for patients, significantly improving comfort, durability and communication.

“It’s a UK success story, with our thriving tech sector supporting our frontline workers as they help our country to emerge from the pandemic. The hoods could be rolled out more widely across the UK and could enable the NHS to treat patients with infectious diseases more safely.”

The BAE Systems Human Factors team conducted trials at the Royal Lancaster Infirmary (RLI), where NHS personnel undertook a simulation of critical activities. Their feedback on the concept and design was used to refine the final product which has been approved by the HSE and British Standards Institution (BSI) for use during the pandemic.

The project began after Stuart and the UHMBT team approached BAE Systems with a request to help design an air-fed mask, following the company’s successful deployment of 3D printed face shields and curtain hooks for the NHS Trust at the start of the pandemic.

Working with the Innovation Agency - the Academic Science Network for the North West Coast - a collaboration was formed to develop the upgraded PPE, which is equipped with an innovative air manifold system with special noise reducing features, a large visor and a protective sheath which extends over the chest and back. State-of-the-art 3D printing technologies were used throughout the prototyping process to accelerate its development and reduce costs, and will continue to be used for production of the complex air manifold system.

Dr Sarah Price, Consultant in Palliative Medicine at UHMBT, said: “One of the main things about the pandemic has been the coming together of people in an almost super-human effort to create something that makes a difference - the Morecambe Bay Hood is a brilliant example of that!

“That human ingenuity, the willpower to make something happen, the belief that you can do it and to have that on our doorstep where it makes a real impact for people who work in the local health service, is fantastic. It feels safe to wear the Morecambe Bay Hood. It’s comfortable, easily cleanable and it means that the whole of your face is on show for those interactions that really matter. These things are real game-changers.”

Steve Timms, Managing Director of BAE Systems’ Submarines business, said: “We’re proud that we’ve been able to donate some of our technical expertise and more than 2,000 hours of voluntary work to help our community and society overcome this technical challenge at a time of real need. Throughout the pandemic our employees have worked hard to help support a wide range of organisations and we’ll continue to play our part in helping where we can.”

Neville Clokey, owner of Lancastle, said: “It’s fantastic to be part of the team that has designed the Morecambe Bay Hood. My wife is a former nurse and both of our children were born at the Royal Lancaster Infirmary so it has been great to be part of this. There’s a feeling of satisfaction in being able to give something back.”

Dr Phil Jennings, Innovation Agency Chief Executive, said: “This innovation in PPE is a true example of collaborative working between local companies, the NHS and the Academic Health Science Network on an innovation which was designed with our NHS colleagues in mind, to protect them as much as the patients they care for.

We've woven together a complex web of ideas, skills and specialisms from across the BAE Systems engineering team to deliver a product that will play a pivotal role in the fight against COVID-19.”

Aaron Cummins, Chief Executive of UHMBT, said: “We would like to say a massive thank you to BAE Systems, Lancastle and everyone who has put their heart and soul into the creation of fantastic Morecambe Bay Hood.

“We are humbled by their generosity, kindness and compassion towards our NHS colleagues and our patients. The Morecambe Bay Hood is a truly great thing to have come out of a time of extreme adversity and we will always be thankful for that.”

Stuart Hosking-Durn added: “We are over the moon with the Morecambe Bay Hood and are delighted that it is now being used within our Trust. We especially wanted a locally-made solution; to put money back into the local community and the local economy. The hoods will be partly made in Barrow and partly made in Lancaster. The icing on the cake is seeing ‘Morecambe Bay Hood’ written on the labels. None of this would have been possible without the amazing support from BAE Systems, the Innovation Agency and Lancastle.”

Notes for editors:

The Powered Air Purifying Respirator consists of a range of components aimed at allowing the wearer to not only be assured of a constant supply of filtered air, but also be able to see and hear the patient receiving treatment. An existing standard issue NHS air pump is used to supply filtered air, but BAE Systems and Lancastle engineers designed components of the accompanying kit to form the hood system.

This includes a headpiece made up of a precision air distribution manifold connected to a cruciform which fits on the users' forehead. The hood itself consists of a visor, a novel detachable neck cuff and a protective outer made of fabric developed especially for this product. Air is transmitted via a hose between the air unit and the air distribution manifold. To reduce the noise of the kit and thereby help medical staff hear and be heard more clearly, several noise reduction innovations have been incorporated into the design by specialist engineers.

Supplementary quotes

Megan Murphree, a Registered Nurse at UHMBT, said: “The fact that our hospital Trust, BAE Systems and Lancastle have put in the time to design the Morecambe Bay Hood which is safe, practical and efficient, just makes us feel looked after; like they really care about the staff and don’t want anybody to catch COVID-19, and to stop the virus from spreading.”

Gemma Byrne, Programme Manager with the Innovation Agency’s Transformation Team, said: “I was delighted to hear about this timely, innovative collaboration and was able to support it by drawing on my experience in the product management of medical devices and contacts.”

About BAE Systems

BAE Systems provides some of the world’s most advanced, technology-led defence, aerospace and security solutions and employs a skilled workforce of some 89,600 people in more than 40 countries. Working with customers and local partners, the Company develops technology that helps to save lives, protect borders and people, strengthen nations and keep critical information and infrastructure secure.

About University Hospitals of Morecambe Bay NHS Foundation Trust

UHMBT employs more than 7,000 people and provides community and hospital services across the Morecambe Bay area; an area covering a thousand square miles in South Cumbria and North Lancashire.

The Trust operates from three main hospitals - Furness General Hospital (FGH) in Barrow, the Royal Lancaster Infirmary (RLI) and Westmorland General Hospital (WGH) in Kendal - as well as from a number of community healthcare premises including Millom Hospital and GP Practice, Queen Victoria Hospital in Morecambe and Ulverston Community Health Centre. All three main hospitals provide a range of planned care including outpatients, diagnostics, therapies, ‘day case’ and inpatient surgery. In addition, a range of local outreach services and diagnostics are provided from community facilities across Morecambe Bay. UHMBT’s community services for adults are provided in people’s homes, community centres, clinics, GP Practices, community hospitals and the main hospitals.

About Lancastle

Lancastle International Ltd is a family-owned and managed company based in Halton near Lancaster in Lancashire. In 1978, Lancastle was approached to produce Racal’s Airstream filter. The success of this product led to a series of product developments over the following two decades establishing Lancastle as one of Europe’s most experienced leading designers and suppliers of powered and supplied air hoods and face seals. Lancastle entered the Foreign Material Exclusion (FME) market in 2008 working with British Energy to redesign fabric FME covers to make them easier to use and more durable in use. Since then the company has grown its range of FME covers and customers to become a leading supplier of FME products for the UK.

For further information regarding this media release, please contact: Ingrid.kent@mbht.nhs.uk or communications.team@mbht.nhs.uk

Gillian Churchill, BAE Systems M: +44 (0) 7921 867103 E: gillian.churchill2@baesystems.com

For associated materials, please visit: https://baesys.resourcespace.com/?c=5031&k=2caac4c47b